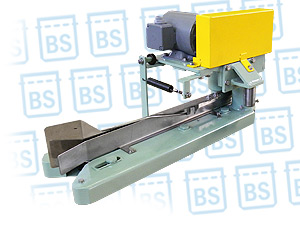

DS-9C High Speed Bag Closer head with Build in Shear knives to cut Thread and Crepe Tape.

High Speed, Self Lubricated, Low Maintenance Bag Closer / Bag Stitcher.Main Feature: Standard able to cut through Crepe tape with pneumatic cutter. Single and Double Needle(s) High Speed Bag Closing / Bag Stitcher Suitable for closing bag materials such as : Paper, Polypropylene (PP) . Enclosed in a self-oil bath lubrication system. This Oil bath protects parts from rusting ensuring higher productivity and a recution in maintenance costs. The unique but simple enclosed oil bath lubrication system greatly extends the life of moving parts and reduces maintenance costs. Main Features of the Newlong Industrial DS-9C

NEWLONG INDUSTRIAL DS-9 SEWING HEAD STITCHER SERIESThe fastest Bag Closer / Bag Stitcher of its kind. Well balanced rotational parts ensure low noise and very little vibration. The low thread tension reduces the risk of the thread thread breaking. Ideally suited for use with high-speed bag filling lines with conveyor belt speeds of 25m/min.

Technical Specifications

*depending on sewing material and operation NLI Newlong Infeeders for use with DS-9C series Sewing head stitcherInfeeders for the DS-9Cnot only optimize easy handling but also add valuable extensions to make it possible to add crepe tape enclosures to Paper bags or fold PP woven bags for a stronger encloser of the bag. For the DS-9 Series we offer 3 different infeeders. Plain sew infeeder, Paper bag Crepe tape + cutter infeeder and PP woven bag folder infeederOptional Add Ons for the DS-9 series

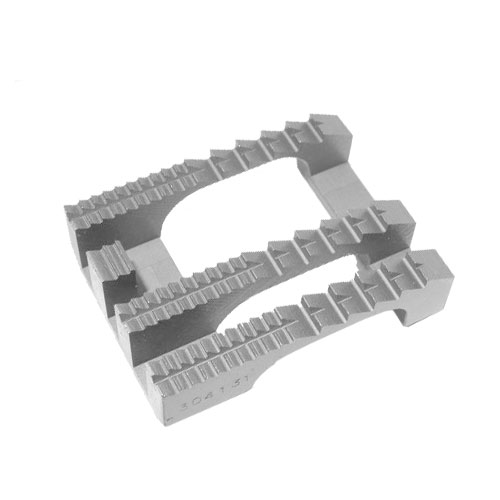

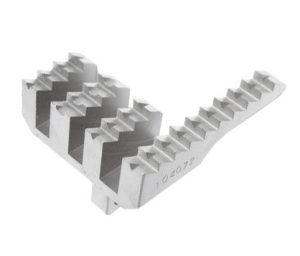

Spare parts for the Newlong DS-9CWe can provide you with original replacement parts for the Newlong Industrial DS-9 series Sewing Head Sticher.

Watch Video Film DS-9C in actionBrand: Newlong Industrial Co., Ltd. Made in Japan |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Newlong DS9 Sewing Head, a precision built sewing head, currently the most versatile of all heads available. Suitable for closing paper, polypropylene, woven, jute and every type of open-mouthed sack. The Newlong DS9 runs smoothly at it’s maximum speed of 2700 rpm, thus maximising your production and giving greater cost efficiency. The oil bath lubrication system is enclosed and completely maintenance free. Moving parts are sealed against dust, ensuring maximum productivity and minimal servicing |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||